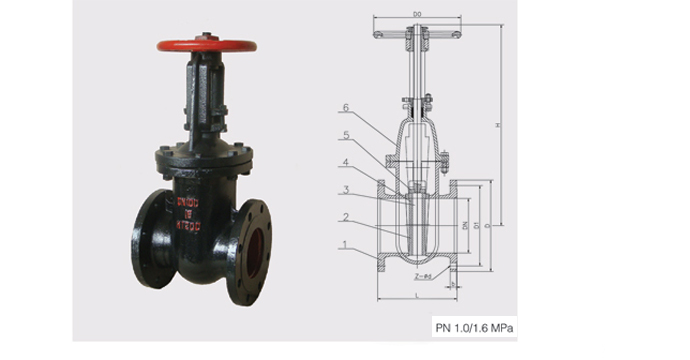

I-valve yesango le-OS&Y ehleli nge-WZ Series Metal

Incazelo:

I-valve yesango le-OS&Y ehleli ngensimbi ye-WZ Series isebenzisa isango lensimbi elithambile eligcina izindandatho zethusi ukuqinisekisa ukuthi livalwe kahle. I-valve yesango le-OS&Y (Outside Screw and Yoke) isetshenziswa kakhulu ezinhlelweni zokufafaza umlilo. Umehluko omkhulu kusuka ku-valve yesango ejwayelekile ye-NRS (Non Rising Stem) ukuthi isiqu kanye ne-nut yesiqu kubekwa ngaphandle komzimba we-valve. Lokhu kwenza kube lula ukubona ukuthi i-valve ivuliwe noma ivaliwe, njengoba cishe ubude bonke besiqu bubonakala lapho i-valve ivuliwe, kanti isiqu asisabonakali lapho i-valve ivaliwe. Ngokuvamile lokhu kuyimfuneko kulezi zinhlobo zezinhlelo ukuqinisekisa ukulawulwa okusheshayo kwesimo sesistimu.

Uhlu lwezinto:

| Izingxenye | Izinto |

| Umzimba | Insimbi ephonswe phansi, insimbi ethambile |

| Idiski | Insimbi ephonswe phansi, insimbi ethambile |

| Isiqu | SS416,SS420,SS431 |

| Indandatho yesihlalo | Ithusi/Ithusi |

| Ibhonethi | Insimbi ephonswe phansi, insimbi ethambile |

| I-stem nut | Ithusi/Ithusi |

Isici:

I-Wedge nut: I-wedge nut yenziwe nge-alloy yethusi enamakhono okugcoba anikeza ukuhambisana okuhle kakhulu nesiqu sensimbi engagqwali.

I-Wedge: I-wedge yenziwe ngensimbi ethambile enezindandatho zobuso ze-copper alloy ezifakwe umshini zibe sezingeni eliphezulu ukuqinisekisa ukuthi i-contact seal ifanelekile ngamasongo esihlalo somzimba. Izindandatho zobuso be-wedge zifakwe ngomshini oqondile futhi ziboshwe ngokuqinile ku-wedge. Iziqondiso eziku-wedge ziqinisekisa ukuvalwa okufanayo naphezu kokucindezeleka okuphezulu. I-wedge ine-bear enkulu yesiqu eqinisekisa ukuthi akukho manzi amile noma ukungcola okungaqongelela. I-wedge ivikelwe ngokugcwele ngengubo ye-epoxy ehlanganisiwe.

Ukuhlolwa kwengcindezi:

| Ingcindezi ejwayelekile | I-PN10 | I-PN16 | |

| Ingcindezi yokuhlola | Igobolondo | 1.5 Mpa | 2.4 Mpa |

| Ukuvala | 1.1 Mpa | 1.76 Mpa | |

Ubukhulu:

| Uhlobo | I-DN(mm) | L | D | D1 | b | Z-Φd | H | D0 | Isisindo (kg) |

| RS | 40 | 165 | 150 | 110 | 18 | 4-Φ19 | 252 | 135 | 11/12 |

| 50 | 178 | 165 | 125 | 20 | 4-Φ19 | 295 | 180 | 17/18 | |

| 65 | 190 | 185 | 145 | 20 | 4-Φ19 | 330 | 180 | 21/22 | |

| 80 | 203 | 200 | 160 | 22 | 8-Φ19 | 382 | 200 | 27/28 | |

| 100 | 229 | 220 | 180 | 24 | 8-Φ19 | 437 | 200 | 35/37 | |

| 125 | 254 | 250 | 210 | 26 | 8-Φ19 | 508 | 240 | 46/49 | |

| 150 | 267 | 285 | 240 | 26 | 8-Φ23 | 580 | 240 | 66/70 | |

| 200 | 292 | 340 | 295 | 26/30 | 8-Φ23/12-Φ23 | 760 | 320 | 103/108 | |

| 250 | 330 | 395/405 | 350/355 | 28/32 | 12-Φ23/12-Φ28 | 875 | 320 | 166/190 | |

| 300 | 356 | 445/460 | 400/410 | 28/32 | 12-Φ23/12-Φ28 | 1040 | 400 | 238/274 | |

| 350 | 381 | 505/520 | 460/470 | 30/36 | 16-Φ23/16-Φ28 | 1195 | 400 | 310/356 | |

| 400 | 406 | 565/580 | 515/525 | 32/38 | 16-Φ28/16-Φ31 | 1367 | 500 | 440/506 | |

| 450 | 432 | 615/640 | 565/585 | 32/40 | 20-Φ28/20-Φ31 | 1460 | 500 | 660/759 | |

| 500 | 457 | 670/715 | 620/650 | 34/42 | 20-Φ28/20-Φ34 | 1710 | 500 | 810/932 | |

| 600 | 508 | 780/840 | 725/770 | 36/48 | 20-Φ31/20-Φ37 | 2129 | 500 | 1100/1256 |