I-TWS Flanged static balancing valve

Incazelo:

I-TWS Flanged Static balancing valve iwumkhiqizo obalulekile webhalansi ye-hydraulic osetshenziselwa ukulawula ukugeleza okunembile kohlelo lwamapayipi amanzi ekusetshenzisweni kwe-HVAC ukuqinisekisa ibhalansi ye-hydraulic engaguquki ohlelweni lwamanzi lonke. Uchungechunge lungaqinisekisa ukugeleza kwangempela kwemishini ngayinye yesiphetho kanye nepayipi ngokuhambisana nokugeleza komklamo esigabeni sokuqala sohlelo ngokusebenza kwesayithi ngekhompyutha yokulinganisa ukugeleza. Uchungechunge lusetshenziswa kabanzi kumapayipi amakhulu, amapayipi amagatsha kanye namapayipi emishini yesiphetho ohlelweni lwamanzi lwe-HVAC. Lungasetshenziswa futhi kwezinye izinhlelo zokusebenza ngesidingo somsebenzi ofanayo.

Izici

Umklamo wepayipi olula kanye nokubala

Ukufakwa okusheshayo nokulula

Kulula ukukala nokulawula izinga lokugeleza kwamanzi endaweni ngekhompyutha yokulinganisa

Kulula ukukala ingcindezi yokwehluka endaweni

Ukulinganisela phakathi komkhawulo we-stroke ngokusethwa kwangaphambili kwedijithali kanye nesibonisi sokusetha kusengaphambili esibonakalayo

Ifakwe ama-cock okuhlola ingcindezi womabili ukuze kulinganiswe ingcindezi ehlukile. Isondo lesandla elingaphakami ukuze kube lula ukusebenza.

Isikulufu sokunciphisa ukushaywa yisifo sohlangothi esivikelwe ngesivalo sokuvikela.

Isiqu sevalvu esenziwe ngensimbi engagqwali i-SS416

Umzimba wensimbi ophonswe ngopende omelana nokugqwala we-epoxy powder

Izicelo:

Uhlelo lwamanzi lwe-HVAC

Ukufakwa

1. Funda le miyalelo ngokucophelela. Ukungayilandeli kungalimaza umkhiqizo noma kubangele isimo esiyingozi.

2. Hlola izilinganiso ezinikezwe emiyalweni nasemkhiqizoni ukuqinisekisa ukuthi umkhiqizo uyafaneleka kuhlelo lwakho lokusebenza.

3. Umfaki kumele abe ngumuntu oqeqeshiwe nonolwazi lwenkonzo.

4. Njalo hlola ngokucophelela uma ukufakwa sekuqediwe.

5. Ukuze umkhiqizo usebenze kahle, umkhuba omuhle wokufaka kumele ufake phakathi ukuhlanza uhlelo, ukwelashwa ngamanzi ngamakhemikhali kanye nokusebenzisa isihlungi somfudlana ohlangothini lwesistimu esingu-50 micron (noma esincane). Susa zonke izihlungi ngaphambi kokuhlanza. 6. Phakamisa ukusebenzisa ipayipi eliqaliwe ukuze uhlanze uhlelo lokuqala. Bese ufaka ivalvu epayipini.

6. Ungasebenzisi izithasiselo zebhoyila, i-solder flux kanye nezinto ezimanzi ezisekelwe ku-petroleum noma eziqukethe uwoyela wamaminerali, ama-hydrocarbon, noma i-ethylene glycol acetate. Izinhlanganisela ezingasetshenziswa, ngokuncibilikiswa kwamanzi okungenani okungu-50%, yi-diethylene glycol, i-ethylene glycol, kanye ne-propylene glycol (izixazululo ze-antifreeze).

7. Ivalvu ingafakwa ngendlela efanayo nomcibisholo emzimbeni wevalvu. Ukufakwa okungalungile kuzoholela ekukhubazekeni kwesistimu ye-hydronic.

8. Ama-cock amabili okuhlola anamathiselwe ebhokisini lokupakisha. Qiniseka ukuthi kufanele afakwe ngaphambi kokuwasebenzisa nokuwahlanza okokuqala. Qiniseka ukuthi awonakalanga ngemva kokufakwa.

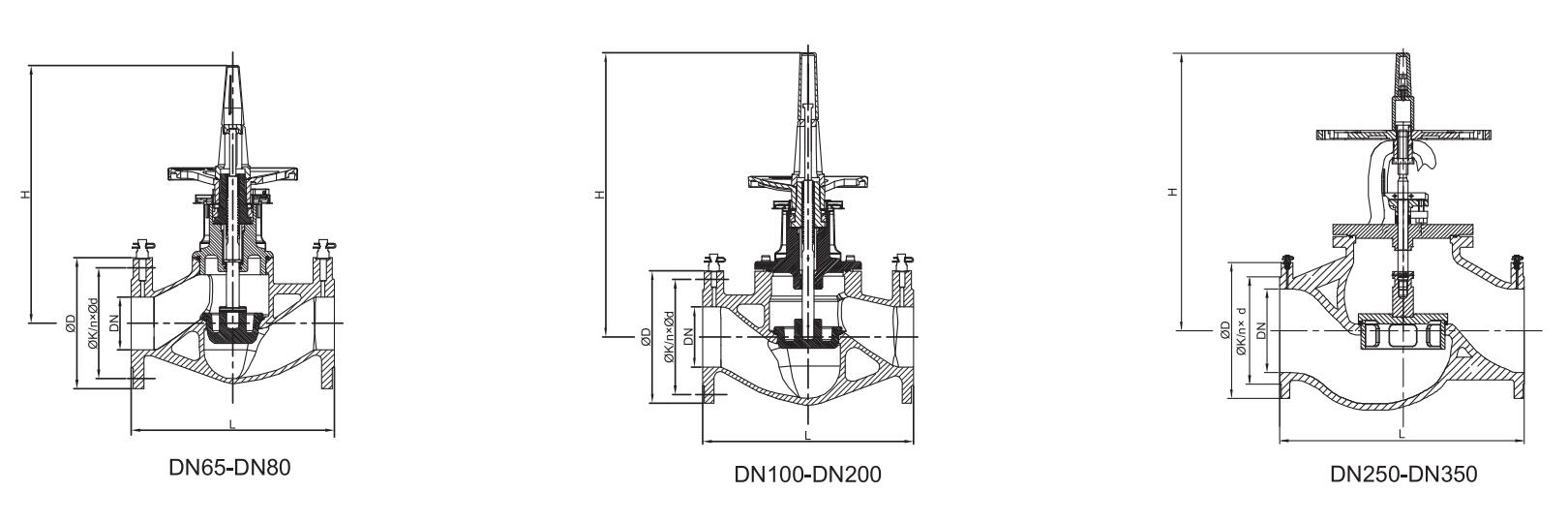

Ubukhulu:

| DN | L | H | D | K | n*d |

| 65 | 290 | 364 | 185 | 145 | 4*19 |

| 80 | 310 | 394 | 200 | 160 | 8*19 |

| 100 | 350 | 472 | 220 | 180 | 8*19 |

| 125 | 400 | 510 | 250 | 210 | 8*19 |

| 150 | 480 | 546 | 285 | 240 | 8*23 |

| 200 | 600 | 676 | 340 | 295 | 12*23 |

| 250 | 730 | 830 | 405 | 355 | 12*28 |

| 300 | 850 | 930 | 460 | 410 | 12*28 |

| 350 | 980 | 934 | 520 | 470 | 16*28 |