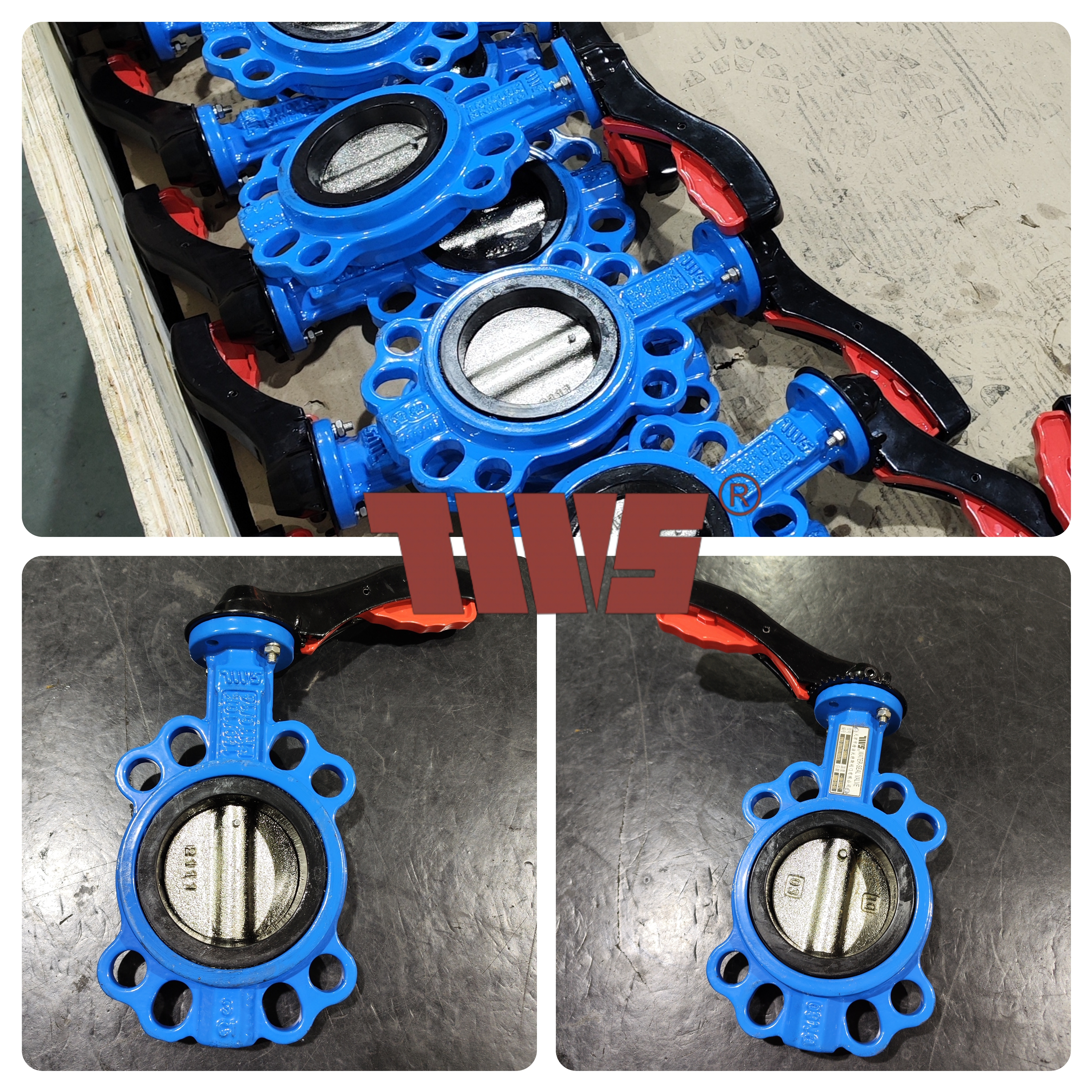

Amavalvu e-Butterfly angamavalvu asetshenziselwa ukulawula noma ukuhlukanisa ukugeleza koketshezi noma igesi ohlelweni lwamapayipi. Phakathi kwezinhlobo ezahlukene zamavalvu e-butterfly emakethe, njenge-wafer butterfly valve,ivalvu yebhabhathane le-lug, i-butterfly enezinhlangothi ezimbili njalo njalo. Ama-valve e-butterfly avaliwe ngerabha avelele ngokusebenza kwawo okuhle kakhulu kokuvala nokuthembeka. Kulesi sihloko, sizohlola izici nezinzuzo zama-valve e-butterfly ahleli ngerabha avela ku-TWS Valve, umenzi owaziwayo embonini.

I-TWS Valve ingumhlinzeki ohamba phambili wama-valve nezinsiza ezisezingeni eliphezulu futhi ama-valve awo e-butterfly ahlala enjoloba awahlukile. I-valve yakhelwe ukuhlinzeka ngokuvala okuqinile, ukuvimbela noma yikuphi ukuvuza noma ukugeleza emuva ohlelweni lwamapayipi. Izihlalo zerabha zenziwe ngezinto eziqinile neziqinile, okuqinisekisa impilo yenkonzo ende kanye nokusebenza okuthembekile ngisho nangaphansi kwezimo zokusebenza ezinzima.

Esinye sezici ezibalulekile ze-TWS Valveivalvu yebhabhathane ehlezi ngerabhaAmandla ayo amahle kakhulu okuvala. Isihlalo serabha sinikeza ukuvala okuqinile okuzungeze idiski, okuvimbela noma yikuphi ukuvuza lapho ivalvu ivaliwe. Lokhu kubaluleke kakhulu ezinhlelweni ezidinga ukulawulwa okunembile kokugeleza koketshezi noma kwegesi. Ngale valve, opharetha bangaqiniseka ukuthi bangafinyelela ukulawulwa okunembile kokugeleza ngaphandle kokuvuza okungadingekile.

Enye inzuzo ye-TWS Valve rubber seated butterfly valve yi-torque ephansi yokusebenza. Umklamo we-valve unciphisa ukungqubuzana phakathi kwediski nesihlalo serabha ukuze kusebenze kahle futhi kube lula. Le torque ephansi yokusebenza ayigcini nje ngokwandisa ukusebenza kahle kwe-valve kodwa futhi inciphisa ukuguguleka kwezingxenye ze-valve, ngaleyo ndlela yandisa isikhathi senkonzo. Ngaphezu kwalokho, i-valve ifakwe ngesimo se-disc esiyingqayizivele esinciphisa ukumelana nokugeleza, okuvumela ukugeleza okusebenzayo nokungavinjelwe.

Ngaphezu kwalokho, amavalvu e-TWS Valve ahlala enjoloba eklanywe ngendlela yokuthi kube lula ukuwafaka nokunakekela. Ivalvu itholakala ngobukhulu obuhlukahlukene futhi ingenziwa ngokwezifiso ukuze ihlangabezane nezidingo ezithile zokufaka amapayipi. Ngenxa yokwakhiwa kwayo okulula, ivalvu ingafakwa noma isuswe ngokushesha futhi kalula, okusindisa isikhathi nomzamo. Ngaphezu kwalokho, izihlalo zerabha zingashintshwa kalula uma kudingeka, kuqedwe isidingo sokushintsha ngokuphelele ivalvu futhi kuncishiswe isikhathi sokungasebenzi.

I-TWS Valve iqinisekisa ukuthi amavalvu ayo e-butterfly ahlala enjoloba ahlangabezana nezindinganiso eziphakeme kakhulu embonini uma kukhulunywa ngekhwalithi nokuqina. Le valve ihlolwa futhi ihlolwe ngokuqinile ukuqinisekisa ukusebenza kwayo nokuthembeka kwayo. Ngokuzibophezela kwe-TWS Valve ekhwalithini, amakhasimende angaqiniseka ukuthi ivalvu abatshala kuyo imali izonikeza ukusebenza okuphezulu futhi imelane novivinyo lwesikhathi.

Ngamafuphi, amavalvu e-TWS Valve ahlala enjoloba ayisisombululo esithembekile nesisebenzayo sokulawula ukugeleza kanye nokuhlukanisa izinhlelo zamapayipi. Ivalvu inikeza opharetha ukusebenza kahle kanye nokuthula kwengqondo ngenxa yamakhono ayo okuvala amahle kakhulu, i-torque ephansi yokusebenza, kanye nokulula kokufakwa nokugcinwa. Kungakhathaliseki ukuthi kuyisicelo sezimboni, sezentengiselwano noma sezindlu, amavalvu e-TWS Valve ahlala enjoloba ayindlela enhle kakhulu yazo zonke izidingo.

Ngaphandle kwalokho, ithimba lonjiniyela nochwepheshe be-TWS Valve abanolwazi lizobe likhona edokodweni ukuze linikeze izivakashi izeluleko zochwepheshe, ukwesekwa kobuchwepheshe kanye nezixazululo ezenziwe ngokwezifiso. Le nkampani izibophezele ekuqondeni izidingo ezihlukile zamakhasimende ayo kanye nokubanikeza izixazululo ezenziwe ngokwezifiso zamavalvu ezihlangabezana nezidingo zabo ezithile, ukuqinisekisa ukusebenza kahle kanye nokuthembeka. Imikhiqizo ihlanganisa futhii-valve yokulinganisela, ivalvu yokuhlola amapuleti amabili e-wafer, i-Y-Strainer njalo njalo.

Isikhathi sokuthunyelwe: Novemba-17-2023