Amavalvu ebhabhathanezidlala indima ebalulekile ekulawuleni ukugeleza koketshezi namagesi ahlukahlukene. Phakathi kwezinhlobo ezahlukene zamavalvu ezimvemvane, amavalvu ezimvemvane ezithwalayo kanye ne-waferamavalvu ebhabhathaneKunezinketho ezimbili ezisetshenziswa kabanzi. Zombili izinhlobo zamavalvu zinemisebenzi ehlukile futhi zifanele ukusetshenziswa okuthile.I-TWSsizohlola ukufana nokwehluka kwazo kulesi sihloko, sinethemba lokukusiza ukuthi wenze izinqumo ezinolwazi lapho ukhetha i-valve efanele.

I. Ukufana phakathi kwabo.

1. UkusebenzaPukugoba.

Womabili amavalvu ebhabhathane ohlobo lwe-wafer kanye namavalvu ebhabhathane ohlobo lwe-lug alawula izinga lokugeleza kwe-medium ngokujikeleza idiski yevalvu. I-engeli yokujikeleza yediski yevalvu ingaba phakathi kwama-degrees angu-0 kuya kwangu-90 kuphela, okusho ukuthi, ivalvu ivuliwe ngokuphelele kuma-degrees angu-90 futhi ivaliwe ngokuphelele kuma-degrees angu-0. Lesi yisimiso esisebenzayo samavalvu ebhabhathane.

2. OkufanayoUbuso Nobuso

Ivalvu yebhabhathane eliyi-wafer kanye nevalvu yebhabhathane eliyi-lug zakhiwe ngohlobo oluncane, oluthatha isikhala esincane futhi olufanele ukufakwa ohlelweni lwamapayipi olunesikhala esincane.

3. Umklamo ojwayelekile:

Zombili zihambisana nezindinganiso zezimboni zomhlaba wonke, kulula ukuzixhuma ngama-flange ajwayelekile, futhi zingashintshwa kalula ezinhlelweni ezikhona.

| Iphrojekthi | Okujwayelekile |

| Umklamo Wenqubo | EN593 | API609 |

| Ubuso Nobuso | I-EN558 | ISO5752 | API608 | BS5155-4 |

| I-Flange Ephezulu | I-ISO5211 |

| Ukubhoboza i-Flange | PN6 | PN10 | PN16 | ASME B16.5 CL150 | I-JIS 10K |

| Isilinganiso Sokucindezela | PN6 | PN10 | PN16 | PN25 | I-CL150 | I-JIS 10K |

| Ukuhlolwa Kokuvala | I-ISO5208 | I-API598 | I-EN12266-1 |

II.Ini's umehluko?

Womabili ama-valve e-butterfly ohlobo lwe-wafer kanye nama-valve e-butterfly ohlobo lwe-lug abhekisela efomini yokuxhuma yama-valve e-butterfly, anobude obufanayo besakhiwo kanye nezinjongo ezifanayo, kodwa kunomehluko omkhulu ekwakhiweni, ekufakweni, ekusetshenzisweni, ezindleleni, nakwezinye izici.

1.UmklamoDizinkomba

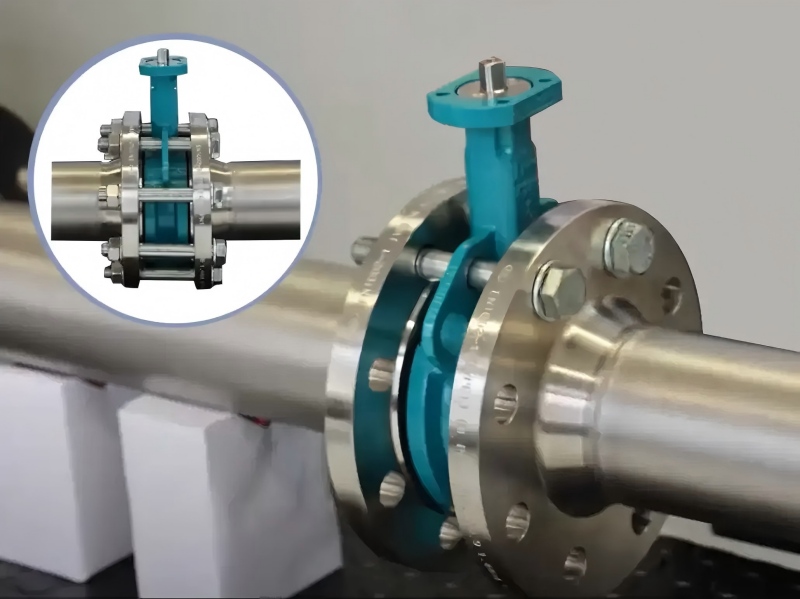

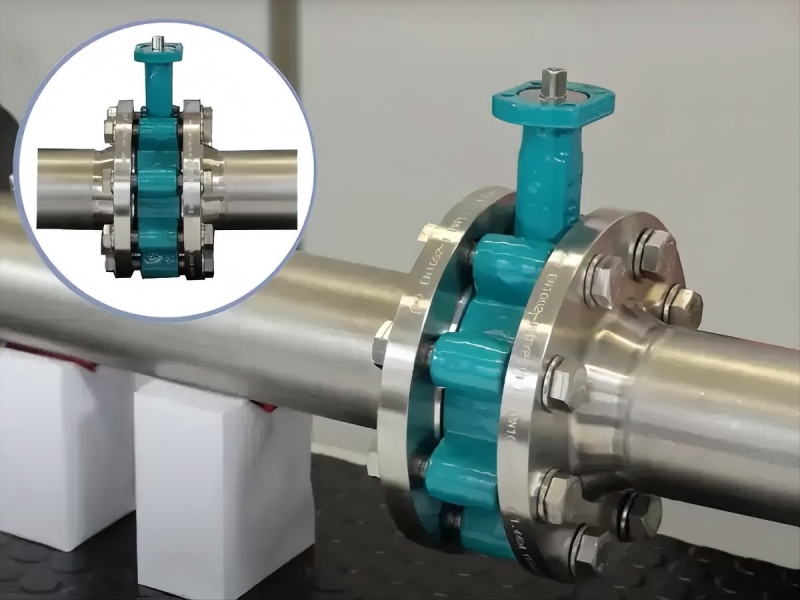

I-Lug butterfly valve: Zombili iziphetho zomzimba we-valve zakhiwe ngama-lug anezintambo, alungele kakhulu ukulungisa i-valve.

I-valve ye-butterfly ye-Wafer: Ngokuphambene nalokho, ayinazo izinto zokufaka ezinentambo, kodwa iboshwe phakathi kwama-flange amabili, ngama-bolts adlula ku-flange yepayipi kanye nomzimba we-valve ukuze ayilungise. Okusho ukuthi, yaklanywa ngokucindezela kwama-bolts acindezela i-flange yepayipi.

2.UkufakwaPinqubo.

Amavalvu e-Lug butterfly afaneleka kumapayipi adinga ukulungiswa njalo noma ukuhlukaniswa njalo. Ama-insert anemicu kulula ukuwafaka nokuwahlukanisa ngaphandle kokulimaza lonke uhlelo lwepayipi. Ivalvu ye-butterfly ephumayo ingafakwa ekugcineni kwepayipi futhi isetshenziswe njengevalvu yokugcina.

- Qinisekisa ukuthi ama-lugs ahambisana kahle nama-flange bolts ukuze ugweme ukucindezela emzimbeni we-valve.

- Sebenzisa izinto ezifanele ze-gasket uma kudingeka ukuvimbela ukuvuza, ikakhulukazi ezinhlelweni zokucindezela okuphakathi.

- Qinisa amabhawodi ngokulinganayo ukuze ugcine ingcindezi efanayo ngaphakathi kwevalvu.

Amavalvu e-butterfly e-Wafer afaneleka kakhulu ukuxhumanisa izinhlangothi zombili zamapayipi ezimweni lapho isikhala silinganiselwe khona, kodwa awakwazi ukusetshenziswa njengamavalvu okugcina njengoba angahlukana.

- Qinisekisa ukuhambisana kwe-flange (isb. ANSI, DIN) ukuqinisekisa ukuvalwa.

- Gwema ukuqinisa kakhulu amabhawodi e-flange ukuze uvimbele ukuguguleka komzimba womshini.

- Kufakwe ohlelweni olune-vibration encane yepayipi ukuvimbela ukukhululeka.

3. Indlela Yokuvala.

I-valve ye-lug butterfly inikeza ukuvala okuqinile ngenxa yokuxhumeka okunezintambo kanye nama-bolt okuphepha, okuqinisekisa ukusebenza okungenawo amanzi futhi kuvimbele ukugeleza koketshezi emuva.

Ngokuphambene nalokho, ivalvu yebhabhathane yohlobo lwe-wafer incike ekucindezelweni phakathi kwama-flange amabili ukuze kufezwe ukuvalwa okuthembekile, ngakho-ke idinga ukufakwa iqondaniswe ngokuphelele nepayipi ukuze kugwenywe ukungalungi nokuvuza.

4. I-DN&I-PN

- I-wafer kuma-valve e-butterfly imvamisa incane kune-DN600, futhi ama-valve e-butterfly e-single flange angasetshenziswa kuma-diameter amakhulu. Ngokuvamile afaneleka ezimweni lapho ingcindezi ingu-≤ PN16.

-Ivalvu ye-lug butterfly inobubanzi obukhulu futhi ingaphatha amazinga aphezulu okucindezela, afinyelela ku-PN25, ngoba ukufakwa kwevalvu ye-lug butterfly kuphephile kakhulu.

5. Ci-ost

Amavalvu e-Lug butterfly kanye namavalvu e-wafer butterfly ahlukile ngendlela engabizi kakhulu.

Amavalvu e-wafer butterfly ngokuvamile ayonga kakhulu ngoba anemiklamo elula, ukucubungula okulula, futhi adinga izinto ezincane.

I-valve ye-lug butterfly idinga ukuthungwa, ngakho-ke inqubo yokugaya iyinkimbinkimbi kakhulu.

III. Cisiphetho

Womabili ama-valve e-lug butterfly kanye nama-valve e-wafer butterfly asetshenziselwa ukulawula ukugeleza koketshezi, kodwa kunomehluko omkhulu ekwakhiweni, ekufakweni, ekuvaleni, ebubanzini, ekulinganisweni kwengcindezi, kanye nasezindleko phakathi kwalokhu okubili. Uma ukhetha, kunganqunywa ngokwezidingo ezithile: uma kudingeka ukuqaqwa nokugcinwa njalo, kungcono ukhethe uhlobo lwendlebe oluvelayo; Uma isikhala sincane futhi izindleko ziyinkinga, i-wafer ekwakhiweni ifaneleka kakhulu. Ukuqonda lo mehluko kungakusiza ukhethe ama-valve ahambisanayo futhi ufinyelele ekulawulweni kokugeleza okusebenzayo nokuthembekile.I-TWSakuyona nje umlingani othembekile wekhwalithi ephezuluamavalvu ebhabhathane, kodwa futhi ineqoqo elijulile lobuchwepheshe kanye nezixazululo ezivuthiwe emikhakheni yeamavalvu esango, ama-valve okuhlola, i-valve yokukhipha umoya, njll. Kungakhathaliseki ukuthi yikuphi ukulawula uketshezi okudingayo, singakunikeza ukwesekwa kwe-valve eyodwa okuchwepheshile nokuphelele. Uma unenhloso yokubambisana noma ukubonisana ngobuchwepheshe, sicela ukhululeke ukuxhumana nathi nganoma yisiphi isikhathi.

Isikhathi sokuthunyelwe: Disemba 11-2025