1. Ukuhlaziywa kwesakhiwo

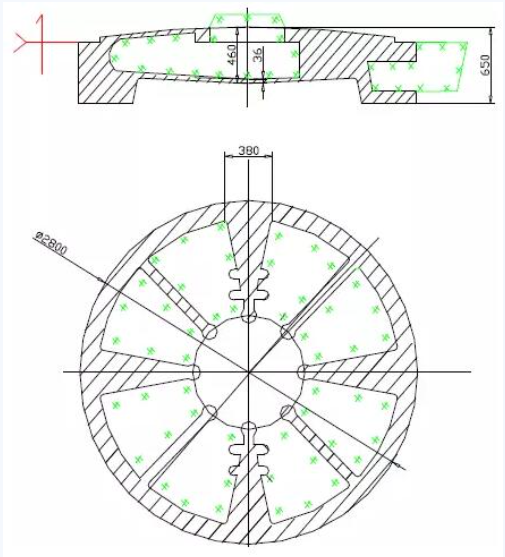

(1) Lokhuivalvu yebhabhathaneinesakhiwo esinjengesikhekhe esiyindilinga, umgodi wangaphakathi uxhunywe futhi usekelwe yizimbambo zokuqinisa ezingu-8, umgodi ophezulu we-Φ620 uxhumana nomgodi wangaphakathi, kanye nokunye okuseleivalvuivaliwe, ingaphakathi lesihlabathi kunzima ukulilungisa futhi kulula ukulishintsha. Kokubili ukukhishwa komoya kanye nokuhlanzwa kwengaphakathi kuletha ubunzima obukhulu, njengoba kuboniswe kuMfanekiso 1.

Ubukhulu bodonga lwezingcezu zokufaka izinto buhluka kakhulu, ubukhulu bodonga obuphezulu bufika ku-380mm, kanti ubukhulu bodonga obuncane bungu-36mm kuphela. Lapho ukuphonswa kuqina, umehluko wokushisa mkhulu, futhi ukuphonswa okungalingani kungadala kalula imigodi yokuncipha kanye nokukhubazeka kwe-porosity yokuncipha, okuzobangela ukuvuza kwamanzi esivivinyweni se-hydraulic.

2. Umklamo wenqubo:

(1) Indawo yokuhlukana iboniswe kuMfanekiso 1. Beka isiphetho esinezimbobo ebhokisini elingaphezulu, yenza umongo wesihlabathi ophelele emgodini ophakathi, bese welula ikhanda eliyinhloko ngendlela efanele ukuze kube lula ukubopha umongo wesihlabathi kanye nokunyakaza komongo wesihlabathi lapho ibhokisi liphendulwa. Lizinzile, ubude bekhanda eliyinhloko le-cantilever lezimbobo ezimbili ezingaboni ohlangothini bude kunobude bomgodi, ukuze isikhungo samandla adonsela phansi somongo wesihlabathi wonke sithambekele ohlangothini lwekhanda eliyinhloko ukuqinisekisa ukuthi umongo wesihlabathi uzinzile futhi uzinzile.

Kusetshenziswa uhlelo lokuthulula oluvaliwe kancane, ∑F ngaphakathi: ∑F ovundlile: ∑F oqondile=1:1.5:1.3, i-sprue isebenzisa ithubhu le-ceramic elinobubanzi bangaphakathi obungu-Φ120, kanti izingcezu ezimbili zezitini eziphikisayo ezingu-200×100×40mm zibekwa phansi ukuvimbela insimbi encibilikisiwe ukuthi ingangeni ngqo. Ukuze kukhunjwe isihlabathi esithintayo, kufakwa isihlungi se-ceramic se-foam esingu-150×150×40 phansi kwesihlungi, kanti amashubhu e-ceramic angu-12 anobubanzi bangaphakathi obungu-Φ30 asetshenziselwa isihlungi sangaphakathi ukuxhuma ngokulinganayo phansi kwesigxobo ngethangi lokuqoqwa kwamanzi phansi kwesihlungi ukuze kwakheke uhlelo lokuthulula oluphansi, njengoba kuboniswe kuMfanekiso 2. I-Essence

(3) Beka imigodi yomoya engu-14 ∮20 esikhumbeni esingaphezulu, beka imbobo yomoya wesihlabathi esingu-Φ200 phakathi kwekhanda eliyinhloko, beka insimbi ebandayo ezingxenyeni ezijiyile nezinkulu ukuqinisekisa ukuqina okulinganayo kokuphonswa, bese usebenzisa isimiso sokukhulisa i-graphitization ukuze ukhansele. I-feeding riser isetshenziselwa ukuthuthukisa isivuno senqubo. Usayizi webhokisi lesihlabathi ungu-3600×3600×1000/600mm, futhi ihlanganiswe ngepuleti lensimbi elingu-25mm ubukhulu ukuqinisekisa amandla anele nokuqina, njengoba kuboniswe kuMfanekiso 3.

3. Ukulawulwa kwenqubo

(1) Ukumodela: Ngaphambi kokumodela, sebenzisa isampula ejwayelekile engu-Φ50×50mm ukuhlola amandla okucindezela esihlabathi se-resin ≥ 3.5MPa, bese uqinisa insimbi ebandayo kanye nesigubhu ukuqinisekisa ukuthi isikhunta sesihlabathi sinamandla anele okuvala i-graphite ekhiqizwa lapho insimbi encibilikisiwe iqinisa ukwanda kwamakhemikhali, futhi uvimbele insimbi encibilikisiwe ukuthi ingathinti ingxenye yesigubhu isikhathi eside ukuze kubangele ukugezwa kwesihlabathi.

Ukwenza umgogodla: Umgogodla wesihlabathi uhlukaniswe izingxenye ezingu-8 ezilinganayo ngama-reinforcement ribs angu-8, axhunywe nge-cavity ephakathi. Azikho ezinye izingxenye zokusekela kanye ne-exhaust ngaphandle kwekhanda eliphakathi nendawo. Uma i-sand core ingenakulungiseka futhi i-Exhaust, i-sand core displacement kanye ne-air holes zizovela ngemva kokuthululwa. Ngenxa yokuthi indawo iyonke ye-sand core inkulu, ihlukaniswe izingxenye ezingu-8. Kumelwe ibe namandla anele kanye nokuqina ukuqinisekisa ukuthi i-sand core ngeke yonakale ngemva kokukhululwa kwesikhunta, futhi ngeke yonakale ngemva kokuthululwa. Kwenzeka ukuguquka, ukuze kuqinisekiswe ubukhulu bodonga obufanayo be-casting. Ngenxa yalesi sizathu, senze ngokukhethekile ithambo elikhethekile le-core, futhi salibopha ethanjeni eliphakathi ngentambo yokungenisa umoya ukuze sidonse igesi yokukhipha umoya ekhanda eliphakathi ukuze siqinisekise ukuthi isikhunta sesihlabathi siqinile lapho senza i-core. Njengoba kuboniswe kuMfanekiso 4.

(4) Ibhokisi lokuvala: Uma ubheka ukuthi kunzima ukuhlanza isihlabathi esingaphakathi kwevalvu yebhabhathane, yonke ingxenye engaphakathi yesihlabathi ipendwe ngezingqimba ezimbili zopende, ungqimba lokuqala lugcotshwa ngopende we-zirconium osekelwe ku-alcohol (iBaume degree 45-55), bese ungqimba lokuqala lupendwe futhi lushiswe. Ngemva kokomisa, penda ungqimba lwesibili ngopende we-magnesium osekelwe ku-alcohol (iBaume degree 35-45) ukuvimbela ukuphonswa ukuthi kunamathele esihlabathini nasekushiseni, okungenakuhlanzwa. Ingxenye eyinhloko yekhanda ilenga epayipini lensimbi le-Φ200 lesakhiwo esiyinhloko sethambo eliyinhloko ngezikulufo ezintathu ze-M25, eziqinisiwe futhi zavalwa ngebhokisi lesihlabathi sesikhunta elingaphezulu elinezikulufo bese kuhlolwe ukuthi ubukhulu bodonga lwengxenye ngayinye buyafana yini.

4. Inqubo yokuncibilikisa nokuthulula

(1) Sebenzisa insimbi yengulube ye-Q14/16# yekhwalithi ephezulu ye-Benxi low-P, S, Ti, bese uyifaka ngesilinganiso esingu-40% ~ 60%; izakhi ezincane ezifana ne-P, S, Ti, Cr, Pb, njll. zilawulwa ngokuqinile ensimbini eqoshiwe, futhi akukho ukugqwala namafutha okuvunyelwe, isilinganiso sokwengeza singama-25% ~ 40%; ishaja elibuyisiwe kumele lihlanzwe ngokudubula ngaphambi kokusebenzisa ukuqinisekisa ukuhlanzeka kweshaja.

(2) Ukulawulwa kwengxenye eyinhloko ngemva kwesithando somlilo: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (insalela): 0.035% ~0.05%, ngaphansi kwesisekelo sokuqinisekisa i-spheroidization, umkhawulo ophansi we-Mg (insalela) kufanele uthathwe ngangokunokwenzeka.

(3) Ukwelashwa kokugonywa kwe-spheroidization: kusetshenziswa ama-spheroidizer ane-magnesium ephansi kanye ne-low-rare-earth, kanti isilinganiso sokwengeza singu-1.0% ~ 1.2%. Ukwelashwa kwe-spheroidization ngendlela evamile yokuhlanza, u-0.15% wokugonywa kanye kuphela umbozwa ku-nodulizer phansi kwephakheji, bese ukugonywa kwe-spheroidization kuqediwe. I-slag ibe isincishiswa ukuze kugonywe okwesibili okungu-0.35%, bese kugonywa ukugeleza okungu-0.15% ngesikhathi sokuthululwa.

(5) Inqubo yokuthulula ngokushesha okuphansi iyasetshenziswa, izinga lokushisa lokuthulula lingu-1320°C~1340°C, kanti isikhathi sokuthulula singamasekhondi angu-70~80. Insimbi encibilikisiwe ayikwazi ukuphazanyiswa ngesikhathi sokuthulula, futhi indebe ye-sprue ihlala igcwele ukuvimbela igesi kanye nezinto ezifakiwe ukuthi zingahileleki ekubunjweni ngokusebenzisa umgodi.

5. Imiphumela yokuhlolwa kokulingisa

(1) Hlola amandla okuthamba kwebhulokhi yokuhlola ehlanganisiwe: 485MPa, ukunwebeka: 15%, ubulukhuni beBrinell HB187.

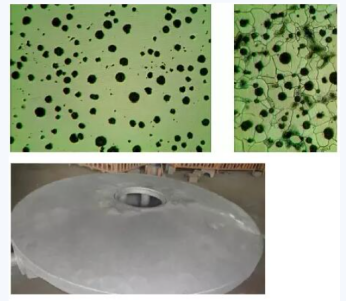

(2) Izinga le-spheroidization lingu-95%, usayizi we-graphite uyibanga lesi-6, kanti i-pearlite ingu-35%. Isakhiwo se-metallographic siboniswe kuMfanekiso 5.

(3) Azikho iziphambeko ezirekhodiwe ezitholakale ekutholakaleni kwamaphutha e-UT kanye ne-MT ezingxenyeni ezibalulekile.

(4) Ukubukeka kuyisicaba futhi kubushelelezi (bheka uMfanekiso 6), ngaphandle kokwenza amaphutha njengokufakwa kwesihlabathi, ukufakwa kwe-slag, ukuvala okubandayo, njll., ubukhulu bodonga buyafana, futhi ubukhulu buhlangabezana nezidingo zemidwebo.

(6) Ukuhlolwa komfutho we-hydraulic ongu-20kg/cm2 ngemuva kokucutshungulwa akubonisanga ukuvuza

6. Isiphetho

Ngokwezici zesakhiwo sale valve yebhabhathane, inkinga yokuguquguquka okungazinzile nokulula kwengxenye enkulu yesihlabathi esiphakathi kanye nokuhlanza isihlabathi okunzima ixazululwa ngokugcizelela ekwakhiweni kohlelo lwenqubo, ukukhiqizwa nokulungiswa kwengxenye enkulu yesihlabathi kanye nokusetshenziswa kwezembozo ezisekelwe ku-zirconium. Ukubekwa kwemigodi yomoya kugwema amathuba okuba nezimbobo ezimbotsheni. Kusukela ohlelweni lokulawula ukushaja kwesithando kanye nohlelo lokugijima, isikrini sesihlungi se-foam ceramic kanye nobuchwepheshe be-ceramic ingate kuyasetshenziswa ukuqinisekisa ubumsulwa bensimbi encibilikisiwe. Ngemuva kokwelashwa okuningi kokugoma, isakhiwo se-metallographic se-castings kanye nokusebenza okubanzi okuhlukahlukene kufinyelele ezidingweni ezijwayelekile zamakhasimende.

KusukelaI-Tianjin Tanggu Water-seal valve Co., Ltd. I-valve yebhabhathane, ivalvu yesango, Isihluzo se-Y, i-valve yokuhlola ipuleti eliphindwe kabili le-waferukukhiqiza.

Isikhathi sokuthunyelwe: Ephreli-29-2023